PCB Assembly Services with SUNTOP Electronics – Your Trusted Manufacturing Partner

SunTop Electronics

In today’s fast-evolving electronics landscape, the demand for high-performance, compact, and reliable circuit boards has never been greater. From smartphones and medical devices to aerospace systems and industrial automation, printed circuit boards (PCBs) are the backbone of modern technology. As complexity increases, so does the need for a trusted partner capable of delivering precision engineering, scalable production, and rigorous quality control.

Enter SUNTOP Electronics — a leading provider of comprehensive PCB Assembly Services designed to meet the diverse needs of innovators, engineers, and OEMs across industries. Whether you're developing prototypes or scaling up to mass production, SUNTOP offers end-to-end solutions that combine cutting-edge technology with decades of manufacturing expertise.

This in-depth guide explores how SUNTOP Electronics excels as a PCB assembly supplier, detailing its core offerings including FPC Assembly, Rigid-Flex PCB Assembly, HDI Assembly, and Multi-layer PCB Assembly. We’ll examine technical capabilities, industry applications, quality assurance protocols, and why choosing the right partner matters in today’s competitive market.

Why Choose SUNTOP Electronics for PCB Assembly?

When it comes to electronics manufacturing, not all providers are created equal. The difference between success and costly delays often lies in the precision, scalability, and reliability of your PCB assembly partner. SUNTOP Electronics stands out by offering:

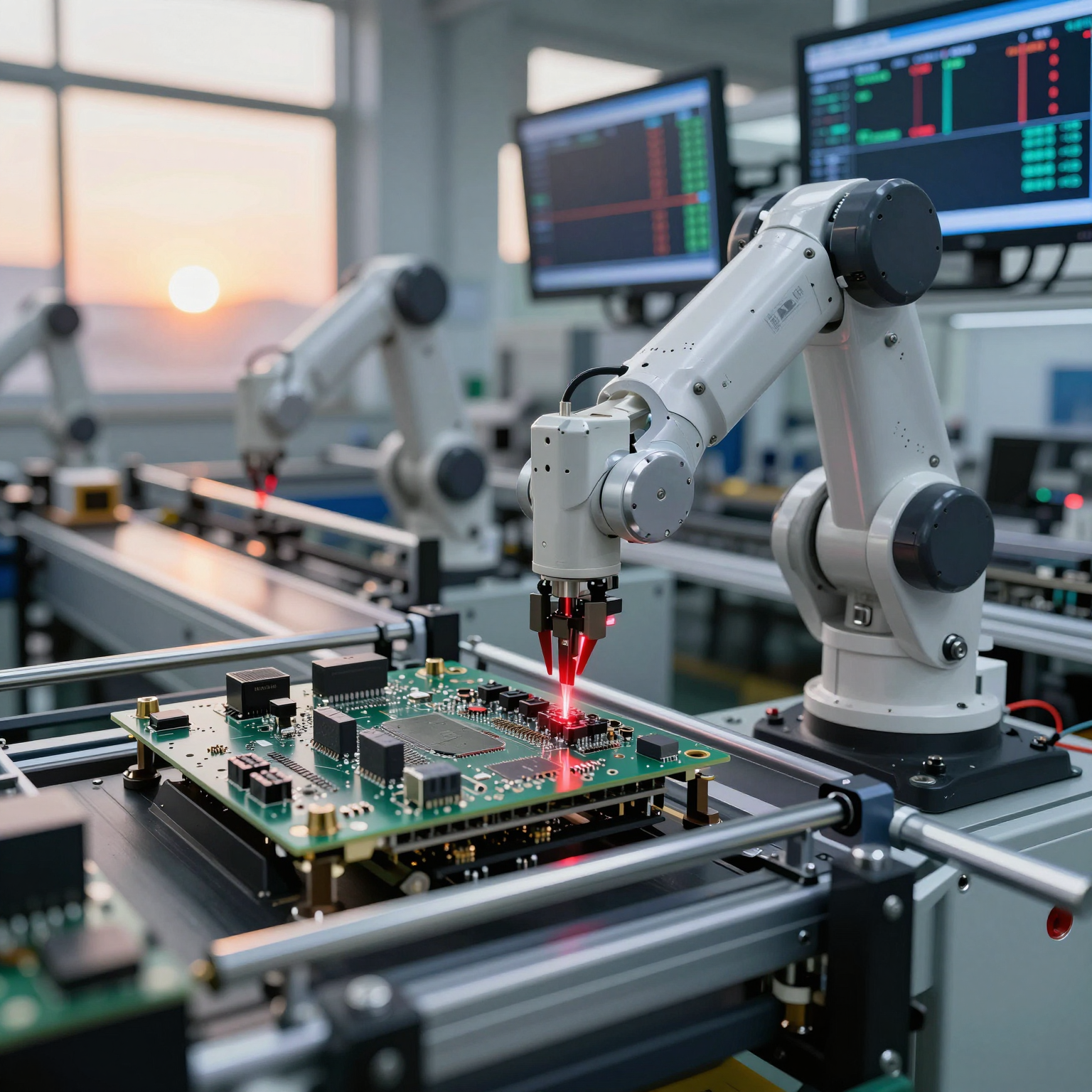

- Advanced surface mount technology (SMT) and through-hole assembly lines

- Full turnkey and consignment production models

- In-house engineering support and design for manufacturability (DFM) analysis

- Strict adherence to IPC-A-610 and ISO 9001 standards

- Transparent communication and real-time project tracking

As a dedicated PCB assembly manufacturer, SUNTOP focuses on delivering consistent quality across every stage — from component sourcing to final testing. With state-of-the-art facilities and an agile supply chain, they cater to startups, mid-sized companies, and large enterprises alike.

But what truly sets SUNTOP apart is its commitment to innovation and customer-centric service. Unlike generic contract manufacturers, SUNTOP tailors its approach based on client requirements, ensuring optimal performance, cost-efficiency, and time-to-market.

Core PCB Assembly Capabilities at SUNTOP Electronics

SUNTOP Electronics specializes in a wide range of PCB assembly services, supporting various board types, technologies, and volume scales. Below is a breakdown of their key capabilities.

1. Standard PCB Assembly

At the foundation of any electronic device lies the standard rigid PCB. SUNTOP provides full-service PCB Assembly using both SMT and through-hole technologies, accommodating components such as resistors, capacitors, ICs, connectors, and more.

Their automated pick-and-place machines achieve placement accuracy down to ±0.025mm, enabling high-density layouts and fine-pitch components. Reflow soldering profiles are precisely controlled to ensure joint integrity, while wave soldering stations handle mixed-technology boards efficiently.

For those seeking a deeper understanding of the entire process, SUNTOP offers a complete guide to PCB assembly that walks through each step from stencil printing to final inspection.

2. Flexible PCB (FPC) Assembly

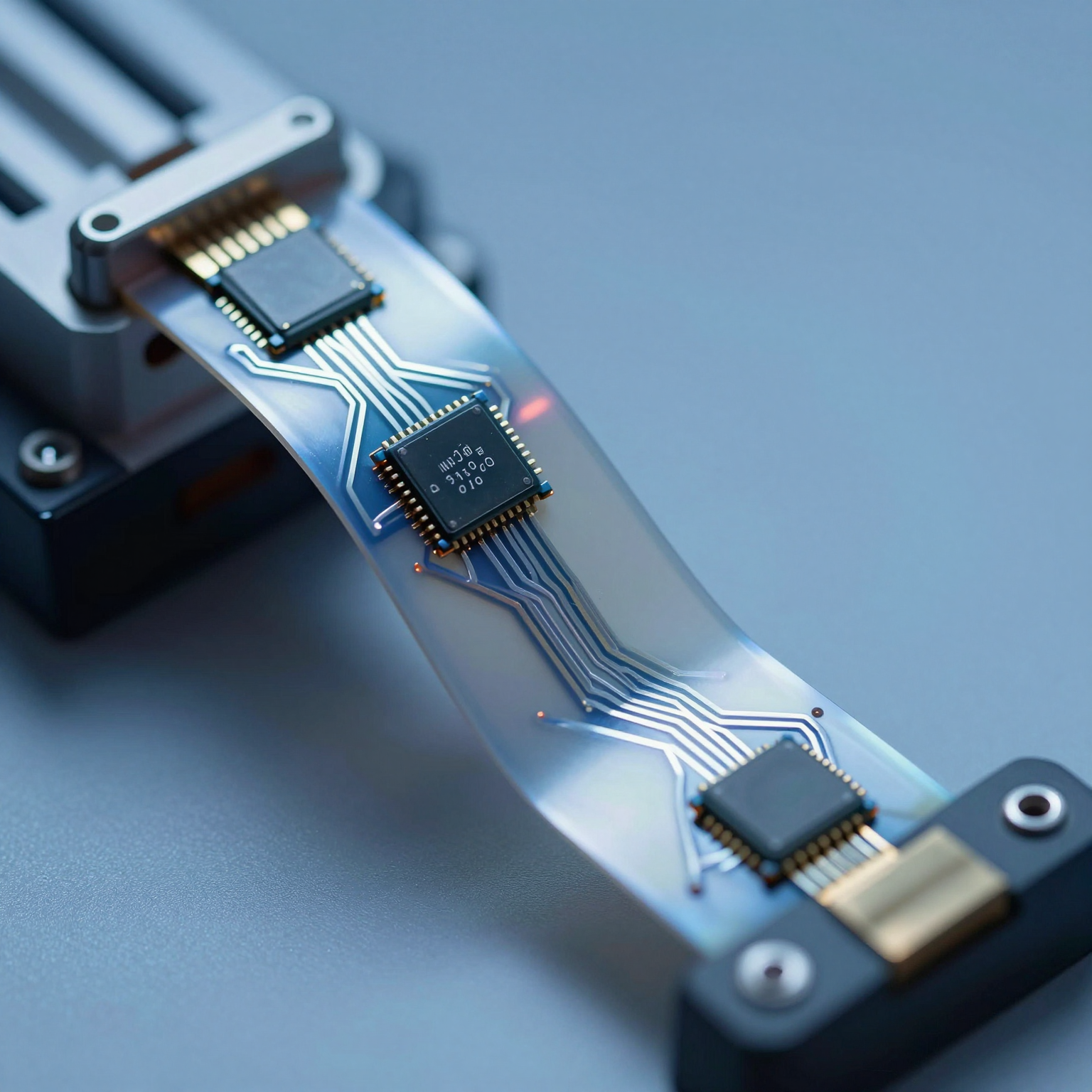

Flexible printed circuits (FPCs) have revolutionized product design by enabling bendable, lightweight interconnects ideal for wearable tech, medical implants, foldable displays, and automotive sensors.

SUNTOP Electronics delivers expert FPC Assembly services tailored to the unique challenges of flexible substrates. These include:

- Handling delicate polyimide materials without warping or tearing

- Using specialized adhesives and stiffeners for component mounting zones

- Implementing low-stress reflow profiles to prevent delamination

- Conducting dynamic flex testing for durability validation

Their engineers apply best practices in flexible PCB design to ensure signal integrity, mechanical resilience, and long-term reliability. For further insights into optimizing FPC layouts, readers can refer to SUNTOP’s detailed article on flexible PCB design best practices.

Applications include:

- Hearing aids and cochlear implants

- Foldable smartphones and tablets

- Endoscopic cameras and surgical robotics

- Automotive infotainment systems

With growing adoption in IoT and miniaturized electronics, FPCs represent one of the fastest-growing segments in PCB manufacturing — and SUNTOP is at the forefront.

3. Rigid-Flex PCB Assembly

Combining the structural stability of rigid boards with the flexibility of FPCs, Rigid-Flex PCBs offer unparalleled advantages in space-constrained and high-reliability environments.

SUNTOP’s Rigid-Flex PCB Assembly services integrate multiple layers of rigid and flexible substrates into a single unified structure. This eliminates the need for connectors and cables, reducing weight, improving reliability, and enhancing signal performance.

Key features of SUNTOP’s rigid-flex capability:

- Up to 20+ layer combinations

- Controlled impedance routing for high-speed signals

- Laser-drilled microvias for dense interconnections

- Selective gold plating for contact fingers and edge connectors

These boards are commonly used in:

- Aerospace and defense avionics

- Unmanned aerial vehicles (UAVs)

- High-end medical diagnostic equipment

- Military communication systems

The assembly process requires meticulous attention to detail due to varying thermal expansion coefficients between rigid and flexible sections. SUNTOP employs advanced fixturing and thermal profiling techniques to ensure uniform soldering across hybrid structures.

Quality is further ensured through rigorous post-assembly inspections, including X-ray analysis and automated optical inspection (AOI), which detect hidden defects like voids and insufficient solder joints.

4. HDI (High-Density Interconnect) Assembly

As consumer electronics continue shrinking in size while increasing in functionality, HDI Assembly has become essential for achieving ultra-compact, high-performance designs.

HDI PCBs utilize microvias, blind/buried vias, and finer trace widths to pack more functionality into smaller footprints. They are critical for smartphones, wearables, AI accelerators, and advanced networking gear.

SUNTOP Electronics offers advanced HDI Assembly services featuring:

- Microvia drilling as small as 0.1mm

- Sequential lamination processes for multi-stage via stacking

- Impedance-controlled designs up to 40 Gbps data rates

- Support for package-on-package (PoP) and flip-chip packaging

Their cleanroom environments and precision alignment systems ensure minimal misregistration during layer stacking — a common challenge in HDI fabrication.

To stay ahead of technological trends, SUNTOP continuously invests in R&D, exploring next-generation HDI architectures. Their thought leadership is evident in publications like the HDI PCB technology outlook for 2026, where they analyze emerging materials, laser drilling advancements, and 3D integration techniques.

Industries benefiting from SUNTOP’s HDI expertise include:

- 5G infrastructure and mmWave modules

- Artificial intelligence hardware

- Augmented reality (AR) and virtual reality (VR) headsets

- Miniaturized implantable medical devices

By combining advanced manufacturing tools with experienced process engineers, SUNTOP ensures reliable yield and performance even in the most demanding HDI applications.

5. Multi-layer PCB Assembly

For complex systems requiring extensive power distribution, ground planes, and signal isolation, Multi-layer PCB Assembly is indispensable.

SUNTOP supports Multi-layer PCB Assembly ranging from 4-layer boards to highly intricate 30+ layer stacks. These are widely used in servers, telecommunications equipment, industrial controls, and military-grade electronics.

Capabilities include:

- Controlled impedance routing with tight tolerances (±10%)

- Power integrity optimization using split planes and decoupling strategies

- Thermal management via internal heat dissipation layers

- Backdrilling to remove stubs in high-speed serial links

Each multilayer board undergoes thorough electrical testing, including flying probe and bed-of-nails fixtures, to verify connectivity and avoid latent failures.

One of the major challenges in multilayer assembly is managing signal integrity at high frequencies. To address this, SUNTOP’s engineers follow proven methodologies in RF and high-speed layout design. Readers interested in these topics can explore their technical resource on RF PCB design and signal integrity at high frequencies.

Additionally, SUNTOP supports advanced packaging technologies such as Ball Grid Arrays (BGAs), Quad Flat No-Lead (QFN), and Land Grid Arrays (LGAs). Specialized processes like BGA rework and underfill application ensure robust connections and resistance to mechanical stress.

For a comprehensive look at overcoming common issues in BGA assembly, see SUNTOP’s expert analysis on BGA assembly challenges and solutions.

Comprehensive Service Offerings Beyond Assembly

While PCB assembly is central to SUNTOP’s value proposition, their service ecosystem extends far beyond basic component mounting. Clients benefit from a fully integrated supply chain and engineering support system.

Electronic Component Sourcing

Component shortages and counterfeit risks remain significant concerns in global electronics manufacturing. SUNTOP mitigates these risks through professional electronic component sourcing and strict vendor qualification programs.

They maintain partnerships with authorized distributors and franchise suppliers, ensuring genuine parts with traceable lot numbers. Their procurement team monitors market availability, lead times, and lifecycle status to proactively manage obsolescence.

Clients can choose between:

- Turnkey model: SUNTOP handles full BOM fulfillment

- Consignment model: Customers supply critical components

- Hybrid model: Mix of supplied and procured parts

This flexibility allows businesses to balance cost, control, and speed depending on their operational needs.

For more details on how they streamline procurement, visit their dedicated page on electronic component sourcing.

Quality Assurance and Testing Protocols

Quality isn’t just a checkpoint — it’s embedded throughout SUNTOP’s operations. Their QA services encompass a systematic, six-phase quality control framework applied from raw material intake to final shipment.

The 6-Step Quality Control Process

-

Incoming Material Inspection

All PCBs, components, and raw materials undergo visual and dimensional checks upon arrival. Components are verified against datasheets and inspected for moisture sensitivity levels (MSL). -

Solder Paste Inspection (SPI)

Automated SPI systems scan deposited solder paste for volume, height, and alignment before component placement. Deviations trigger immediate corrective actions. -

Automated Optical Inspection (AOI)

Post-reflow and post-wave soldering, AOI machines inspect solder joints, polarity, missing parts, and bridging. False positives are minimized through machine learning algorithms trained on defect libraries. -

X-Ray Inspection (AXI)

Hidden joints — especially under BGAs and QFNs — are analyzed using AXI to detect voids, insufficient solder, and misalignment. -

In-Circuit Testing (ICT) & Flying Probe Test

Electrical continuity, shorts, opens, and passive values are validated using ICT fixtures or flying probe testers for low-volume runs. -

Functional Testing (FCT)

Fully assembled boards are tested under simulated operating conditions to verify performance, power consumption, and communication interfaces.

This structured approach aligns with the 6-step quality control process outlined in SUNTOP’s public resources, reinforcing transparency and accountability.

Moreover, their facility adheres to environmental standards such as RoHS and REACH compliance, ensuring products meet global regulatory requirements.

Design for Manufacturability (DFM) Analysis

Even the most brilliant circuit design can fail if it's not optimized for production. SUNTOP provides free DFM reviews to identify potential issues early — saving time, money, and frustration.

Their engineers evaluate:

- Component spacing and orientation

- Pad sizes and footprint accuracy

- Via placement and net connectivity

- Thermal relief and copper balancing

- Panelization efficiency and depaneling methods

Feedback is delivered promptly with actionable recommendations, allowing designers to refine layouts before fabrication begins.

This proactive collaboration reduces iterations, accelerates prototyping, and improves first-pass yields.

Supply Chain Optimization

Global disruptions have underscored the importance of resilient supply chains. SUNTOP addresses this through strategic inventory planning, dual sourcing, and demand forecasting analytics.

They leverage digital platforms to monitor component availability in real time, helping clients navigate shortages and allocate resources efficiently. Their blog post on PCB supply chain optimization for 2026 highlights emerging strategies like nearshoring, buffer stocking, and predictive procurement.

Such forward-thinking approaches empower customers to maintain production continuity even amid market volatility.

Industries Served by SUNTOP Electronics

SUNTOP’s versatile capabilities make them a preferred partner across numerous high-tech sectors. Their industries served by PCB manufacturer span mission-critical and consumer-driven markets alike.

Medical Devices

From patient monitors to MRI machines, reliability is non-negotiable in healthcare. SUNTOP produces Class II and III medical PCBAs compliant with ISO 13485 standards. Their cleanrooms and traceability systems ensure sterility and audit readiness.

Industrial Automation

Robotic controllers, PLCs, HMI panels, and sensor networks rely on rugged, thermally stable PCBs. SUNTOP’s assemblies withstand harsh environments, vibration, and extended temperature ranges.

Telecommunications

5G base stations, fiber optic transceivers, and network switches require high-frequency, low-loss PCBs. SUNTOP supports Rogers, Teflon, and other specialty laminates for RF and microwave applications.

Consumer Electronics

Smart home devices, audio gadgets, and portable electronics benefit from SUNTOP’s rapid turnaround and scalable production. Their expertise in miniaturization enables sleek, feature-rich designs.

Automotive and EVs

Advanced driver-assistance systems (ADAS), infotainment units, battery management systems (BMS), and lighting modules demand automotive-grade reliability. SUNTOP follows AEC-Q100 guidelines for component selection and performs thermal cycling tests to validate longevity.

Aerospace and Defense

Mission-critical avionics, radar systems, and satellite communications require extreme durability and zero failure tolerance. SUNTOP’s rigid-flex and HDI solutions meet MIL-PRF-31032 and DO-254 standards.

For a complete overview of vertical markets, visit the official industries served by PCB manufacturer page.

Technology Comparison: SMT vs Through-Hole Assembly

Understanding the differences between assembly methods is crucial when selecting a manufacturing partner. SUNTOP excels in both SMT vs through-hole assembly, applying the right technique based on application needs.

| Feature | SMT (Surface Mount Technology) | Through-Hole |

|---|---|---|

| Component Size | Smaller, lighter | Larger, bulkier |

| Board Density | High (ideal for HDI) | Lower |

| Production Speed | Fast (automated placement) | Slower (manual insertion) |

| Vibration Resistance | Good (with proper design) | Excellent |

| Cost Efficiency | Higher for volume | Higher for low volume |

| Common Use Cases | Smartphones, laptops, wearables | Power supplies, transformers, connectors |

While SMT dominates modern electronics due to its compactness and automation compatibility, through-hole remains vital for high-power and high-reliability applications. SUNTOP integrates both seamlessly within the same production line, offering mixed-technology assembly for hybrid designs.

A detailed comparison is available in their educational article: SMT vs through-hole assembly.

Surface Finishes and Reliability

The choice of PCB surface finish significantly impacts solderability, shelf life, and long-term reliability. SUNTOP supports multiple finishes tailored to environmental and performance demands.

Common options include:

- HASL (Hot Air Solder Leveling) – Economical and durable; suitable for general-purpose use

- Lead-Free HASL – RoHS-compliant alternative to traditional HASL

- ENIG (Electroless Nickel Immersion Gold) – Flat surface ideal for fine-pitch and BGA components

- ENEPIG (Nickel-Palladium-Gold) – Superior wire bonding and oxidation resistance

- OSP (Organic Solderability Preservative) – Low-cost, eco-friendly; short shelf life

- Immersion Silver/Tin – Balanced cost and performance for moderate environments

Each finish has trade-offs in terms of cost, flatness, corrosion resistance, and compatibility with assembly processes. SUNTOP advises clients on optimal selections based on storage duration, operating environment, and end-use conditions.

Their comprehensive guide on understanding PCB surface finishes helps engineers make informed decisions aligned with product goals.

How to Get Started with SUNTOP Electronics

Partnering with SUNTOP is simple and efficient. Here’s how to begin:

-

Submit Your Project Requirements

Upload your Gerber files, BOM, and assembly drawings via their secure portal. -

Receive a Free DFM Review

Within 24 hours, their engineering team analyzes your design and suggests improvements. -

Get a Competitive Quote

Based on volume, complexity, and delivery timeline, SUNTOP provides transparent pricing with no hidden fees. -

Approve and Proceed to Production

Once approved, SUNTOP manages everything — from sourcing to shipping — keeping you informed every step of the way.

Ready to move forward? You can easily get a PCB quote directly through their website. Alternatively, reach out to their team via the contact PCB manufacturer form for personalized assistance.

For new clients wanting to learn more about company values and history, the about PCB assembly company section offers valuable background.

Final Thoughts: Why SUNTOP Stands Out

In a crowded field of contract manufacturers, SUNTOP Electronics distinguishes itself through technical excellence, operational transparency, and unwavering commitment to quality.

As a true PCB assembly supplier, they go beyond mere production — acting as a strategic extension of your engineering team. Whether you need FPC Assembly for a groundbreaking wearable, Rigid-Flex PCB Assembly for aerospace systems, HDI Assembly for next-gen computing, or Multi-layer PCB Assembly for industrial controls, SUNTOP delivers precision and reliability at scale.

Their investment in automation, quality systems, and supply chain resilience ensures that clients receive not only functional boards but trusted partners capable of navigating the complexities of modern electronics manufacturing.

For businesses looking to accelerate innovation without compromising on quality, SUNTOP Electronics represents a powerful ally in bringing ideas to life.

Explore More Resources

Stay updated with the latest trends and technical insights from SUNTOP:

- Visit the PCB blog for expert articles

- Explore PCB manufacturing capabilities

- Browse PCB products and case studies

- Learn about additional PCB services like box build and cable harnessing

Whether you’re designing your first prototype or scaling a mature product line, SUNTOP’s ecosystem of knowledge and support empowers smarter decisions.

Conclusion

The future of electronics depends on intelligent, reliable, and scalable PCB assembly. With evolving demands for miniaturization, speed, and energy efficiency, partnering with a capable manufacturer is no longer optional — it’s imperative.

SUNTOP Electronics meets this challenge head-on, offering world-class PCB Assembly Services that cover the full spectrum of modern PCB technologies. From FPC Assembly to HDI Assembly, their expertise spans the most advanced and demanding applications.

Backed by rigorous quality controls, responsive customer service, and deep technical know-how, SUNTOP continues to earn trust among innovators worldwide.

If you're searching for a dependable PCB assembly manufacturer who combines precision, agility, and integrity, look no further than SUNTOP Electronics.

Start your journey today — because great products begin with great partnerships.