6 Step Quality Control Process

David Lee

Why Quality Control Matters in PCB Manufacturing

Before diving into the specifics of our 6-step process, it’s essential to understand why quality control is so critical in PCB manufacturing and PCB Assembly.

A printed circuit board serves as the nervous system of any electronic device. It connects components electrically and mechanically, enabling everything from smartphones to satellites to function correctly. However, due to increasingly complex designs, tighter tolerances, higher component densities, and demand for smaller form factors, the margin for error has never been slimmer.

Defects such as solder bridges, open circuits, misaligned components, insufficient solder joints, or delamination can result in:

- Intermittent failures

- Reduced product lifespan

- Field recalls

- Safety hazards

- Reputational damage

- Increased warranty costs

Moreover, many industries—including automotive, medical, military, and telecommunications—are governed by strict regulatory standards like IPC-A-610, ISO 9001, IATF 16949, and AS9100. Non-compliance with these standards can disqualify a manufacturer from bidding on contracts or lead to legal consequences.

This is where a structured, repeatable, and auditable quality control process becomes indispensable. At SUNTOP Electronics, we don’t treat QC as a final inspection checkpoint—we integrate it into every stage of the workflow, from design review to final testing and shipment.

By implementing a proactive rather than reactive approach, we catch potential issues early, reduce rework, improve yield rates, and ultimately deliver products that customers can trust.

Now, let’s explore the six pillars of our quality assurance framework.

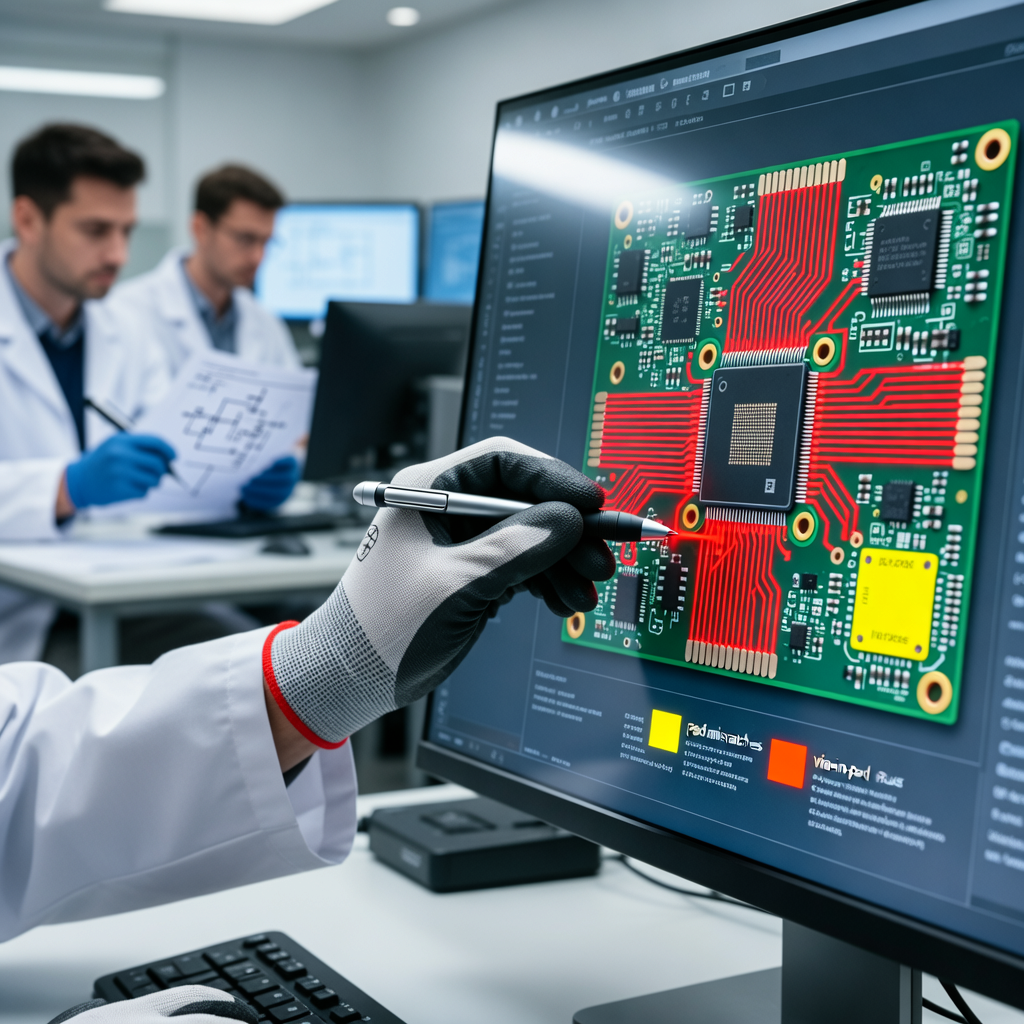

Step 1: Design for Manufacturability (DFM)

and Design for Assembly (DFA) Review

The foundation of any successful PCB manufacturing project begins long before materials hit the production floor—it starts with the design.

Even the most elegant schematic can fail during fabrication or assembly if it doesn’t account for real-world manufacturing constraints. That’s why our first quality control step involves a thorough Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis.

When a customer submits their Gerber files, BOM (Bill of Materials), and assembly drawings, our engineering team conducts a comprehensive review using advanced software tools and decades of hands-on experience. We check for:

- Trace width and spacing violations

- Solder mask clearance issues

- Pad size mismatches

- Component placement density

- Thermal relief design

- Via-in-pad complications

- Footprint accuracy

- Polarized component orientation

- Test point accessibility

For example, if a designer uses a component footprint that doesn’t match the actual package dimensions—or places surface-mount devices too close together—we flag the issue immediately and work collaboratively with the client to resolve it.

This pre-production audit prevents costly mistakes down the line. According to industry studies, fixing a design flaw after manufacturing has begun can cost up to 100 times more than addressing it during the design phase.

Additionally, our DFM/DFA review helps optimize the design for automated processes such as pick-and-place machines and reflow ovens, ensuring smoother transitions between stages and reducing the risk of machine errors or jams.

At SUNTOP, we believe that transparency and collaboration are key. That’s why we provide detailed DFM reports with visual annotations and recommendations, empowering our clients to make informed decisions about their designs.

You can learn more about best practices in PCB design by reading our guide on flexible PCB design best practices.

Step 2: Raw Material Inspection and Component Verification

Once the design is approved, the next critical juncture in our quality control process is material verification. In PCB Assembly, the integrity of raw materials—including bare boards, electronic components, solder paste, and packaging materials—directly impacts the final product's reliability.

We source materials only from certified, reputable suppliers who comply with RoHS, REACH, and other environmental and safety regulations. But certification alone isn’t enough. Every batch undergoes rigorous incoming inspection.

Bare Board Inspection

For PCB fabrication, we inspect incoming bare boards for:

- Dimensional accuracy

- Copper thickness

- Dielectric properties

- Plating quality

- Surface finish uniformity (e.g., ENIG, HASL, Immersion Silver)

- Warpage or bowing

Using optical comparators, micrometers, and automated optical inspection (AOI) systems, we verify that each panel meets IPC Class 2 or Class 3 requirements based on the application.

Any deviation triggers a quarantine procedure and initiates communication with the supplier for resolution.

Electronic Component Sourcing and Authentication

Component authenticity is a growing concern in the electronics supply chain. Counterfeit parts—recycled, remarked, or substandard components—can mimic genuine ones but often fail prematurely under stress.

To combat this, SUNTOP employs multiple verification techniques:

- Visual Inspection: Microscopic examination of markings, leads, and packaging.

- X-Ray Analysis: To detect internal die differences or wire bonding anomalies.

- Decapsulation Testing: For high-reliability applications, we perform destructive physical analysis when necessary.

- Lot Traceability: Every component lot is logged with date codes, manufacturer information, and supplier details for full traceability.

We also maintain strong relationships with authorized distributors and use independent third-party verification services when sourcing hard-to-find or obsolete parts.

Our electronic component sourcing team works closely with clients to ensure BOM compliance while offering alternatives when needed—without compromising quality.

This level of diligence ensures that only verified, high-integrity materials enter the production environment, forming a solid foundation for consistent output.

Step 3: Automated Optical Inspection (AOI)

After Solder Paste Application

With materials cleared and ready, the PCB Assembly process moves into the surface mount technology (SMT) line. One of the earliest points where defects can occur is during solder paste deposition—the process of applying precise amounts of conductive paste onto pads before component placement.

Even minor inconsistencies here—such as insufficient paste, smearing, or misalignment—can lead to poor solder joints, tombstoning, or opens/shorts later on.

To prevent this, we deploy Automated Optical Inspection (AOI) immediately after the stencil printing stage.

Our AOI systems use high-resolution cameras and sophisticated image-processing algorithms to scan each board and compare the results against the original CAD data. The system evaluates:

- Volume and height of solder deposits

- Positional accuracy relative to fiducial markers

- Bridging or excess paste between adjacent pads

- Missing or incomplete prints

If discrepancies are detected, the system flags the board in real time, halting further processing until corrective action is taken. Operators then recalibrate the printer, clean the stencil, or adjust squeegee pressure as needed.

This real-time feedback loop not only improves first-pass yield but also contributes to continuous process improvement. Over time, statistical data collected from AOI inspections helps identify trends—like recurring misalignments linked to specific board sizes or stencils—allowing us to refine our procedures proactively.

Because solder paste quality directly influences downstream reliability, this third step acts as a crucial gatekeeper before expensive components are placed on the board.

Step 4: Post-Pick-and-Place and Reflow Oven Monitoring

After successful solder paste application, the next major milestone is component placement via high-speed pick-and-place machines. These robotic systems place thousands of components per hour with micron-level precision. While highly accurate, they are not immune to errors—especially with ultra-fine pitch ICs, micro BGAs, or mixed-technology boards.

Therefore, our fourth QC step includes both post-placement AOI and reflow profile monitoring.

Post-Placement AOI

Immediately after the pick-and-place machine finishes loading components, another round of AOI takes place. This inspection verifies:

- Correct component presence and absence

- Polarity and orientation (especially for diodes, capacitors, and ICs)

- Placement accuracy (X, Y, theta alignment)

- Skewed or lifted leads

- Damaged or cracked components

Again, any deviation triggers an alert, allowing technicians to intervene before the board enters the reflow oven. Catching placement errors now avoids thermal damage and wasted energy later.

Reflow Oven Thermal Profiling

Equally important is ensuring that the reflow soldering process follows an optimal thermal profile. Different components, board thicknesses, and solder alloys require specific heating and cooling curves to achieve reliable intermetallic bonds without damaging sensitive parts.

At SUNTOP, we use multi-zone convection reflow ovens equipped with thermocouples and data loggers. Before full-scale production runs, we run test boards with temperature sensors attached to monitor actual heat exposure across various zones of the board.

We analyze peak temperatures, ramp rates, soak times, and cooling slopes to ensure they align with the solder paste manufacturer’s specifications (e.g., SAC305 alloy). Real-time adjustments are made as needed to maintain consistency.

Furthermore, we perform regular maintenance and calibration of all equipment to prevent drift over time—a common cause of latent defects.

By combining post-placement verification with precise thermal control, we maximize solder joint integrity and minimize the risk of cold joints, voiding, or thermal shock.

For deeper insights into assembly challenges, especially with advanced packages, read our article on BGA assembly challenges.

Step 5: In-Circuit Testing (ICT) and Functional Testing (FCT)

Once the boards exit the SMT line and any through-hole components are wave-soldered or hand-soldered, they proceed to electrical testing—the fifth and one of the most critical steps in our quality control process.

Testing confirms not just that components are present and properly soldered, but that the circuit behaves as intended.

We employ two primary types of electrical validation: In-Circuit Testing (ICT) and Functional Circuit Testing (FCT).

In-Circuit Testing (ICT)

ICT uses a bed-of-nails fixture that makes contact with test points across the board. It applies small electrical signals to measure:

- Continuity and isolation (opens and shorts)

- Resistor, capacitor, and inductor values

- Diode polarity and transistor functionality

- Voltage levels at key nodes

This granular level of testing allows us to pinpoint exact locations of faults—even buried within multilayer boards—and distinguish between manufacturing defects and design issues.

ICT is particularly effective for medium-to-high volume productions where fixture investment is justified.

Functional Circuit Testing (FCT)

While ICT checks individual components and connections, FCT evaluates the entire system under simulated operating conditions. Our custom-built test rigs power up the board and run firmware or diagnostic routines to validate:

- Power supply stability

- Communication interfaces (USB, Ethernet, SPI, I²C)

- Sensor inputs and actuator outputs

- Display functionality

- Software boot sequences

FCT mimics real-world usage scenarios, helping uncover subtle timing issues, firmware bugs, or intermittent behaviors that static tests might miss.

Both ICT and FCT generate detailed pass/fail logs, which are stored digitally for audit purposes. Failed units are routed to our repair station, where skilled technicians diagnose and correct the fault before retesting.

These testing protocols ensure that every shipped unit functions exactly as specified, significantly reducing field failure rates.

For those interested in learning more about testing methodologies, visit our page on PCB quality testing.

Step 6: Final Visual Inspection and Packaging Audit

The final frontier of our 6-step quality control process is the last line of defense: Final Visual Inspection (FVI) and Packaging Audit.

Even after passing AOI, X-ray, and functional tests, human oversight remains invaluable. Trained inspectors examine each board under magnification to catch cosmetic defects that machines may overlook—such as:

- Flux residue

- Scratches or dents on silkscreen

- Misprinted labels or barcodes

- Bent pins or damaged connectors

- Improper conformal coating coverage

Inspectors follow IPC-A-610 acceptance criteria, classifying defects according to severity (minor, major, critical) and determining whether rework or rejection is required.

All accepted boards then undergo a final packaging review. This includes verifying:

- Proper anti-static bagging

- Desiccant inclusion

- Moisture indicator cards (for MSD-sensitive components)

- Labeling accuracy (part number, revision, date code)

- Carton strength and sealing

Proper packaging protects the product during transit and storage, preventing electrostatic discharge (ESD), moisture ingress, and mechanical damage—all of which could compromise performance upon arrival.

Each batch is assigned a unique tracking number, linking it back to production records, test results, and material lots. This end-to-end traceability supports rapid root cause analysis in case of field returns and satisfies compliance requirements for regulated industries.

Only after clearing this final checkpoint are the boards released for shipment.

How Our 6-Step Process Delivers Value

Implementing a comprehensive quality control system isn’t just about avoiding defects—it’s about delivering tangible value to our customers.

Here’s how SUNTOP’s 6-step approach translates into real-world benefits:

1. Higher Yield Rates and Lower Costs

By catching issues early—especially during DFM and incoming inspection—we minimize scrap, rework, and delays. This leads to improved throughput and lower overall production costs, which we pass on to our clients.

2. Faster Time to Market

Fewer surprises mean fewer iterations. With fewer bottlenecks caused by late-stage failures, projects move smoothly from prototype to mass production.

3. Greater Reliability and Customer Satisfaction

Consistently high-quality products enhance brand reputation and reduce post-sale support burdens. Whether you’re launching a consumer gadget or deploying life-saving medical equipment, reliability is non-negotiable.

4. Regulatory Compliance and Risk Mitigation

Our documented QC procedures align with international standards, making audits easier and reducing liability risks. Full traceability ensures accountability at every level.

5. Scalability Across Industries

From IoT wearables to ruggedized industrial controllers, our flexible QC framework adapts to diverse requirements. Explore the range of markets we serve via our industries served by PCB manufacturer page.

Continuous Improvement: Beyond the Six Steps

While our 6-step process forms the core of our quality control strategy, we view quality as a journey—not a destination.

We continuously invest in:

- Advanced inspection technologies (e.g., 3D AOI, AXI for hidden solder joints)

- Staff training and certification programs

- Lean manufacturing principles

- Data analytics and SPC (Statistical Process Control)

- Supplier development initiatives

Regular internal audits, customer feedback loops, and participation in industry forums help us stay ahead of emerging challenges and technological shifts.

We also embrace digital transformation—using ERP and MES systems to track work orders, manage inventory, and monitor KPIs in real time. This visibility enables faster decision-making and greater responsiveness.

Partner with SUNTOP Electronics for Reliable PCB Manufacturing

At SUNTOP Electronics, we don’t just build PCBs—we build trust. Our 6-step quality control process reflects our unwavering commitment to excellence in PCB manufacturing and PCB Assembly.

From initial design consultation to final delivery, we partner with engineers and businesses worldwide to bring innovative ideas to life—with precision, reliability, and peace of mind.

Whether you need low-volume prototypes, high-volume production runs, or full turnkey solutions including component sourcing and box-build assembly, our experienced team is ready to support your success.

Ready to get started? Find out more about our capabilities on our PCB manufacturing capabilities page, or reach out today to contact PCB manufacturer directly.

For new projects, simply submit your files to get a PCB quote and let us show you how quality is engineered into every board we produce.