Global Electronic Components Sourcing: Strategies, Challenges, and Best Practices

Heros Rising

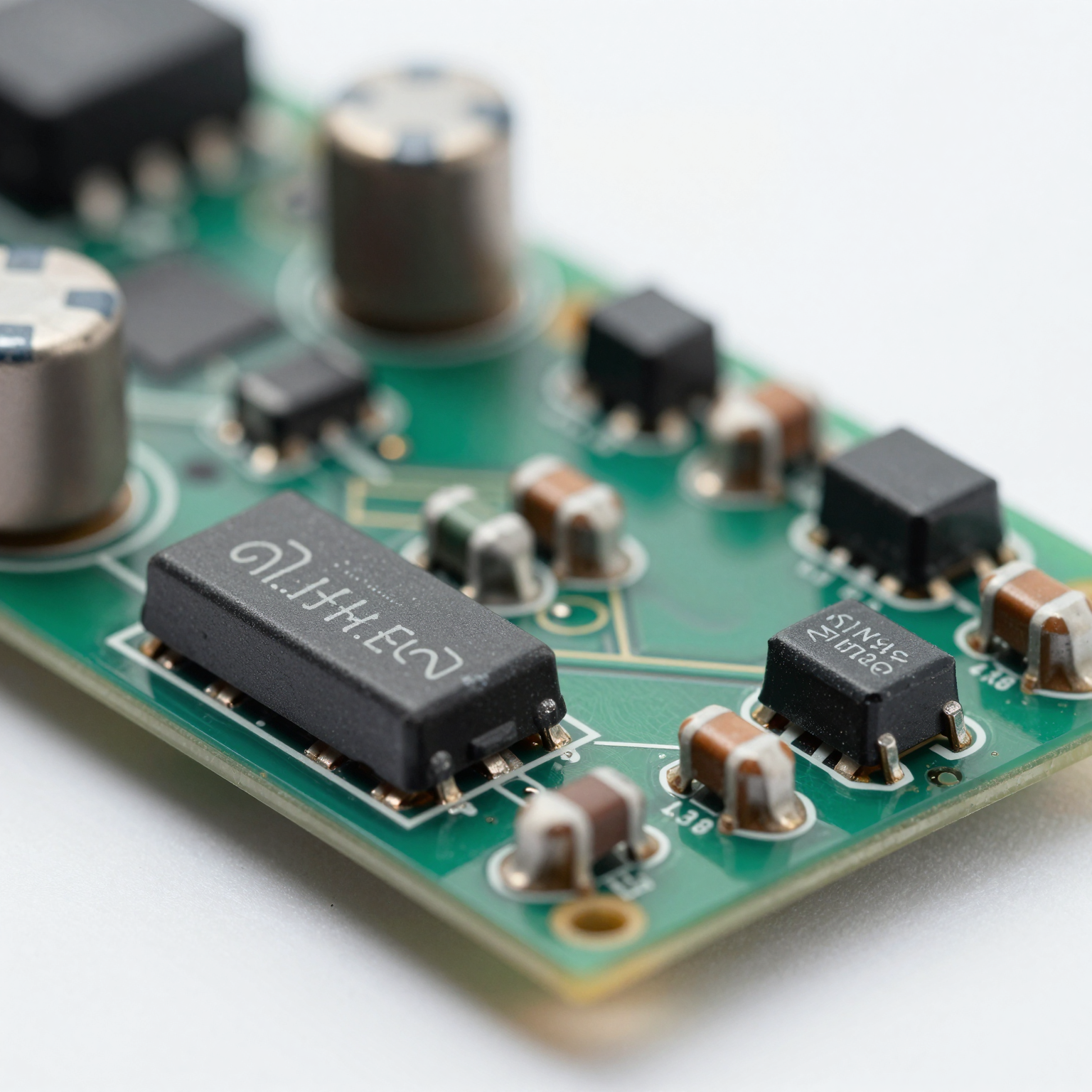

In today’s interconnected world, Electronic Components Sourcing has become a cornerstone of successful electronics manufacturing. As products grow more complex and demand for innovation accelerates, companies are increasingly relying on global networks to procure resistors, capacitors, integrated circuits, connectors, and other essential parts. Whether you're developing consumer gadgets, industrial automation systems, or medical devices, the ability to source high-quality components efficiently can make or break your time-to-market and product reliability.

This comprehensive guide explores the dynamics of global Electronic Components Sourcing, covering key strategies, common challenges, risk mitigation techniques, and best practices to help manufacturers and design engineers build resilient supply chains.

Why Global Sourcing Matters in Electronics

The shift toward global Electronic Components Sourcing is driven by several factors:

- Cost Efficiency: Many component manufacturers operate in regions with lower production costs, such as Southeast Asia and China, offering competitive pricing.

- Specialized Expertise: Certain countries have developed niche capabilities in producing advanced semiconductors or passive components.

- Scalability: Global suppliers often have the infrastructure to support large-volume orders required by OEMs.

- Technological Access: Proximity to innovation hubs allows faster adoption of new technologies like IoT sensors, AI chips, and power-efficient modules.

However, globalization also introduces complexity. Supply chains now span continents, involving multiple tiers of suppliers, logistics providers, and regulatory bodies—each presenting potential points of failure.

Key Components in the Electronics Supply Chain

Understanding what’s being sourced is crucial. The most commonly procured electronic components include:

Passive Components

Resistors, capacitors, and inductors form the backbone of nearly every circuit board. While seemingly simple, shortages in multilayer ceramic capacitors (MLCCs) have historically disrupted entire industries.

Active Components

Integrated circuits (ICs), microcontrollers, transistors, and diodes fall into this category. These are often custom-designed or sourced from major semiconductor firms like Texas Instruments, NXP, or STMicroelectronics.

Electromechanical Parts

Switches, relays, and connectors bridge electrical and mechanical functions. Their availability can be constrained due to long lead times and limited manufacturing capacity.

Discrete Semiconductors

Diodes, thyristors, and MOSFETs are vital for power management and signal control applications.

Each of these categories requires careful planning during the Electronic Components Sourcing process, especially when dealing with obsolescence, lifecycle changes, or geopolitical disruptions.

Challenges in Global Electronic Components Sourcing

Despite its advantages, global sourcing comes with significant hurdles.

1. Supply Chain Volatility

Events such as pandemics, natural disasters, trade wars, and political instability can disrupt shipping routes and factory operations. For example, port closures during the COVID-19 pandemic caused massive delays in component deliveries worldwide.

2. Component Shortages and Allocation

High-demand components—especially advanced ICs—are often placed under allocation, meaning suppliers prioritize top-tier customers. Smaller businesses may struggle to secure consistent supply.

3. Counterfeit Components

A persistent threat in global markets, counterfeit parts can enter the supply chain through unauthorized distributors or gray market channels. These substandard components compromise product performance and safety.

According to the U.S. Department of Commerce, counterfeit electronics pose a serious risk to national security and public safety, particularly in defense and aerospace sectors [^1].

4. Long Lead Times

Lead times for certain components have stretched from weeks to over a year. This makes accurate forecasting essential but difficult in fast-moving markets.

5. Regulatory Compliance

Different countries impose varying standards on materials (e.g., RoHS, REACH) and import/export controls. Non-compliance can result in shipment rejections or fines.

Strategies for Effective Electronic Components Sourcing

To overcome these challenges, companies must adopt proactive and strategic approaches.

Diversify Your Supplier Base

Relying on a single supplier increases vulnerability. Establish relationships with multiple vendors across different regions. Consider dual-sourcing critical components whenever possible.

Leverage Authorized Distributors

Work exclusively with authorized distributors or franchise partners of original component manufacturers. They provide traceability, authenticity guarantees, and technical support.

Invest in Forecasting and Inventory Planning

Use historical data and market intelligence to predict demand accurately. Implement just-in-time (JIT) inventory models cautiously, balancing cost savings with buffer stock for critical items.

Partner with Full-Service Manufacturing Providers

Collaborating with an experienced PCB assembly services provider can streamline Electronic Components Sourcing. These partners often have established procurement networks, volume buying power, and quality assurance protocols that reduce your operational burden.

For instance, many turnkey PCBA providers offer end-to-end solutions—from component sourcing to final assembly and testing—ensuring seamless integration between design and production phases.

Use Digital Procurement Platforms

Modern sourcing platforms leverage AI and big data to monitor inventory levels, track price fluctuations, and identify alternative parts. Tools like Sourcengine, Octopart, and Chip1Stop allow real-time comparison across global suppliers.

Risk Mitigation in Component Sourcing

Managing risk is not optional—it's a necessity in modern electronics manufacturing.

Conduct Supplier Audits

Regularly evaluate suppliers based on quality certifications (e.g., ISO 9001), delivery performance, and financial stability. On-site audits can reveal red flags before they impact your production line.

Implement Obsolescence Management

Monitor lifecycle statuses using tools like IHS Markit or SiliconExpert. When a component nears end-of-life (EOL), proactively seek second-source alternatives or plan last-time buys.

Enforce Quality Control Processes

Every batch of incoming components should undergo rigorous inspection. Techniques such as X-ray analysis, decapsulation testing, and electrical parameter verification help detect counterfeits and defects early.

Some manufacturers follow a 6-step quality control process to ensure consistency and compliance throughout the supply chain.

Secure Long-Term Agreements

Negotiate multi-year contracts with key suppliers to lock in pricing and availability. Include clauses for volume flexibility and force majeure protection.

The Role of Technology in Modern Sourcing

Digital transformation is reshaping Electronic Components Sourcing:

Blockchain for Traceability

Emerging blockchain solutions enable transparent tracking of components from raw material to finished product, reducing fraud and improving accountability.

Artificial Intelligence and Predictive Analytics

AI-powered systems analyze global trends, weather patterns, shipping data, and geopolitical events to forecast disruptions and recommend alternative sourcing paths.

Cloud-Based Collaboration Tools

Engineering, procurement, and manufacturing teams can now collaborate in real time using shared dashboards, ensuring alignment on part selection, availability, and substitutions.

These advancements empower companies to respond faster and smarter to changing conditions in the global marketplace.

Regional Trends in Electronic Components Sourcing

Geography plays a pivotal role in shaping sourcing strategies.

Asia-Pacific: The Manufacturing Powerhouse

China, Taiwan, South Korea, and Malaysia dominate semiconductor fabrication and component manufacturing. However, rising labor costs and U.S.-China trade tensions have prompted some companies to explore nearshoring options.

North America: Reshoring Momentum

There’s growing investment in domestic semiconductor production, spurred by initiatives like the CHIPS and Science Act. While still import-dependent, the region is rebuilding its manufacturing base.

Europe: Focus on Sustainability and Innovation

European nations emphasize green manufacturing and ethical sourcing. Regulations like RoHS and WEEE influence component design and disposal practices globally.

Southeast Asia: Rising Alternative

Countries like Vietnam, Thailand, and India are emerging as viable alternatives for both component production and final assembly, thanks to favorable policies and expanding infrastructure.

Building a Resilient Sourcing Strategy

Creating a robust Electronic Components Sourcing framework involves more than finding cheap parts—it's about building agility, transparency, and trust.

Start by mapping your entire supply chain, identifying single points of failure. Then develop contingency plans, including pre-qualified alternate suppliers and approved substitute components.

Engage cross-functional teams early in the design phase. Design for supply chain resilience (DfSR) encourages engineers to select readily available, standard components instead of highly specialized ones unless absolutely necessary.

Finally, foster strong partnerships. Reliable suppliers act as extensions of your team, providing insights into market shifts, advising on lifecycle planning, and supporting rapid prototyping efforts.

Conclusion: Mastering the Art of Global Sourcing

As electronics continue to evolve at breakneck speed, mastering Electronic Components Sourcing is no longer optional—it's a competitive imperative. Companies that invest in diversified supplier networks, embrace digital tools, and prioritize quality and compliance will be best positioned to thrive in an unpredictable global landscape.

Whether you're launching a startup or scaling an enterprise, remember that effective sourcing starts with collaboration. By partnering with trusted electronic component sourcing experts and leveraging proven methodologies, you can ensure your products reach the market on time, within budget, and to the highest standards of performance and reliability.

For those seeking expert guidance, consider exploring resources like the complete guide to PCB assembly to deepen your understanding of how component sourcing integrates with overall manufacturing success.