Mastering OEM Electronic Components Sourcing for Efficient PCB Production

Rossanie Rolling

In today’s fast-paced electronics industry, the success of any Original Equipment Manufacturer (OEM) hinges not only on innovative design but also on efficient and reliable production processes. One of the most critical aspects of this process is OEM electronic components sourcing—the strategic acquisition of essential parts such as resistors, capacitors, integrated circuits, connectors, and more. Effective sourcing ensures that manufacturers can deliver high-quality products on time, within budget, and in compliance with global standards.

This comprehensive guide explores the intricacies of OEM electronic components sourcing, covering best practices, common challenges, risk mitigation strategies, and how partnering with the right PCB assembly services provider can streamline your supply chain and enhance overall operational efficiency.

What Is OEM Electronic Components Sourcing?

OEM electronic components sourcing refers to the process by which original equipment manufacturers procure electronic parts needed to build their end products. Unlike retail purchasing, OEM-level sourcing involves large-volume orders, long-term contracts, and deep collaboration with suppliers and contract manufacturers.

These components are typically used in printed circuit board (PCB) assembly, where they are mounted onto boards using surface mount technology (SMT) or through-hole techniques. The goal of effective sourcing is to secure high-quality components at competitive prices while maintaining continuity of supply and minimizing risks related to obsolescence, counterfeiting, and geopolitical disruptions.

Why Strategic Sourcing Matters in Electronics Manufacturing

The electronics supply chain is complex and highly sensitive to market fluctuations. A single component shortage can halt production lines, delay product launches, and damage customer relationships. That's why strategic OEM electronic components sourcing has become a cornerstone of modern manufacturing.

Ensuring Supply Chain Resilience

Global events like the semiconductor shortage during the pandemic have underscored the importance of resilient sourcing strategies. By diversifying suppliers, forecasting demand accurately, and building strong vendor relationships, OEMs can reduce dependency on single sources and respond quickly to disruptions.

Cost Optimization Without Compromising Quality

Strategic sourcing allows OEMs to negotiate better pricing through volume discounts and long-term agreements. However, cost savings should never come at the expense of reliability. High-quality components ensure fewer field failures, lower warranty costs, and enhanced brand reputation.

Supporting Innovation and Time-to-Market

Rapid innovation requires access to cutting-edge components. Proactive sourcing enables OEMs to integrate new technologies faster, accelerating product development cycles and gaining a competitive edge.

Key Steps in the OEM Electronic Components Sourcing Process

A well-structured sourcing strategy follows several key steps to ensure efficiency, transparency, and quality control throughout the procurement lifecycle.

1. Component Specification and Bill of Materials (BOM)

Management

The foundation of successful sourcing begins with an accurate and detailed Bill of Materials (BOM). This document lists every component required for PCB assembly, including part numbers, manufacturer names, tolerances, packaging types, and lifecycle status.

Engineering teams must work closely with procurement specialists to ensure BOM accuracy and identify potential dual-source alternatives early in the design phase.

2. Supplier Identification

and Qualification

Not all component suppliers are created equal. OEMs must evaluate potential vendors based on:

- Quality certifications (e.g., ISO 9001, IATF 16949)

- Traceability and anti-counterfeit measures

- Financial stability and production capacity

- Geographic location and logistics capabilities

Establishing pre-approved vendor lists (AVLs) helps standardize sourcing decisions and reduces onboarding time for new projects.

3. Request for Quotation (RFQ) and Negotiation

Once qualified suppliers are identified, OEMs issue RFQs detailing quantity requirements, delivery timelines, and technical specifications. Responses are evaluated not just on price, but also on lead times, minimum order quantities (MOQs), and payment terms.

Negotiating favorable terms—such as consignment inventory, vendor-managed inventory (VMI), or blanket purchase orders—can significantly improve cash flow and supply flexibility.

4. Order Placement and Inventory Management

After selecting a supplier, purchase orders are issued, and tracking systems monitor shipment progress. Just-in-time (JIT) inventory models help minimize warehousing costs, but require precise coordination between procurement, logistics, and production planning.

Many OEMs now rely on electronic data interchange (EDI) platforms to automate ordering and improve visibility across the supply chain.

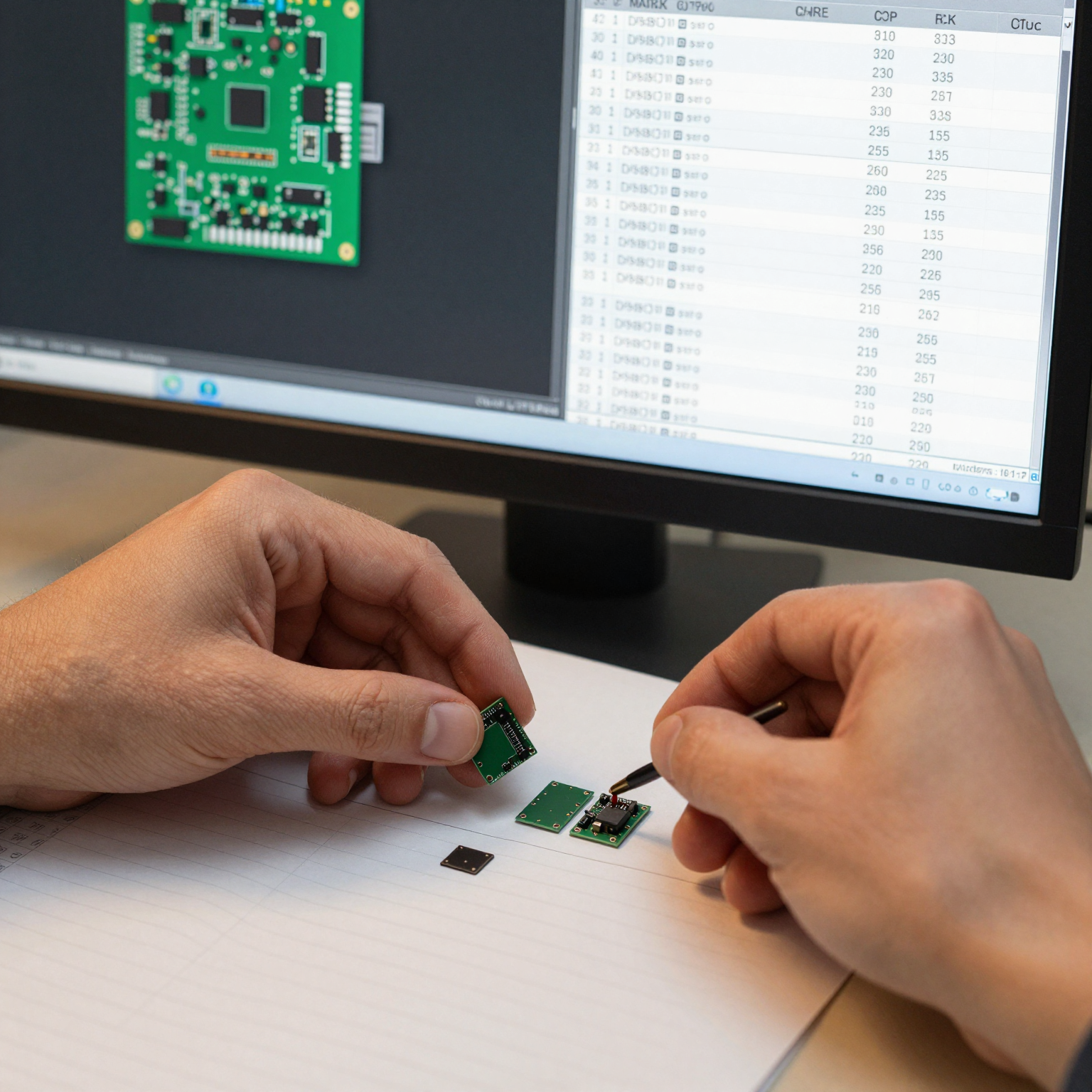

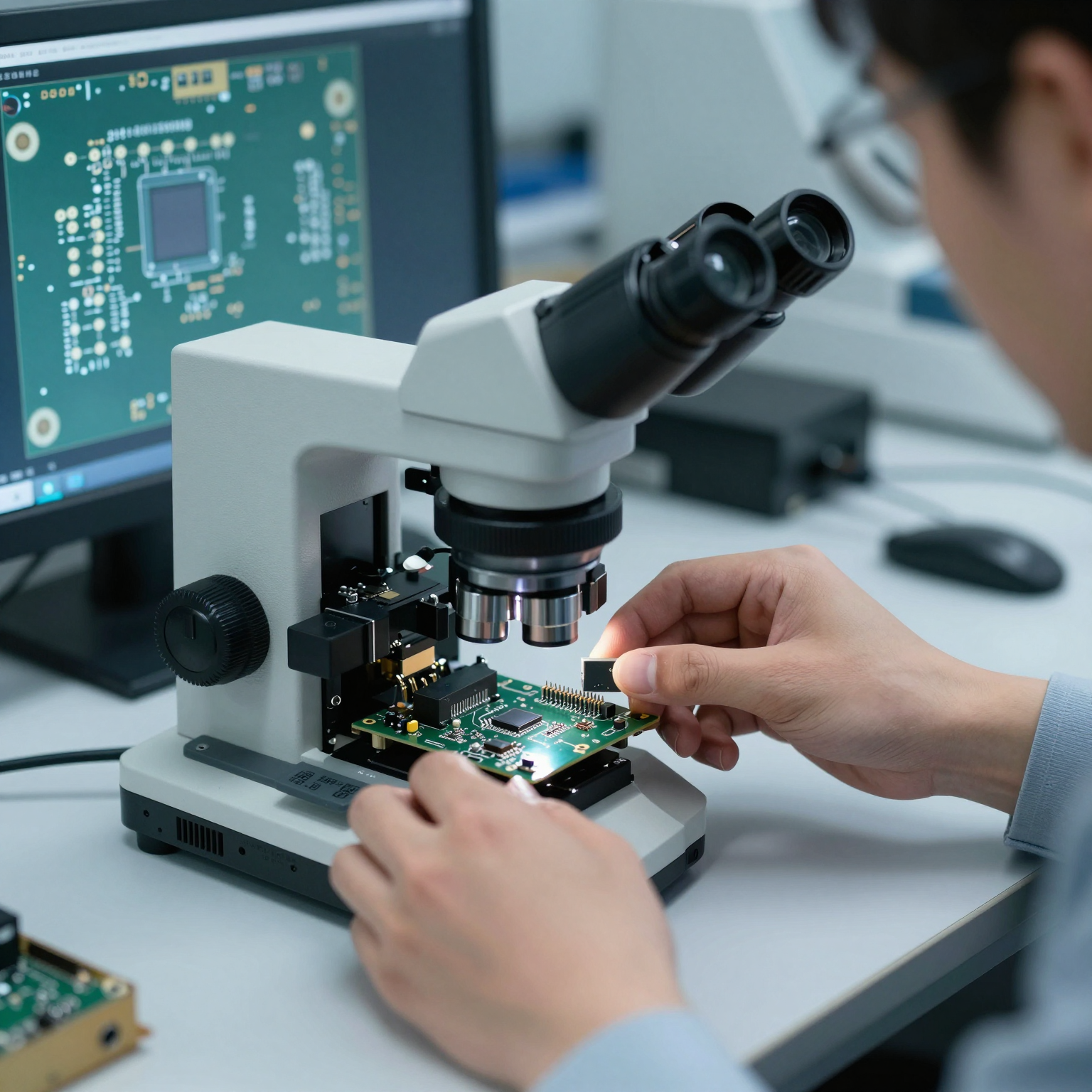

5. Incoming Inspection

and Quality Assurance

Upon arrival, components undergo rigorous inspection to verify authenticity, functionality, and conformance to specifications. Techniques such as X-ray analysis, decapsulation testing, and electrical parameter verification help detect counterfeit or substandard parts.

Integrating these checks into a broader OEM electronic components sourcing strategy protects product integrity and regulatory compliance.

Common Challenges in OEM Electronic Components Sourcing

Despite its importance, OEM electronic components sourcing comes with significant challenges that can impact production timelines and profitability.

Component Obsolescence

Electronic components often have short lifecycles due to rapid technological advancement. When a part becomes obsolete, redesign efforts may be required, leading to delays and increased costs. Proactive lifecycle monitoring and last-time buy (LTB) planning are essential to mitigate this risk.

Counterfeit Parts

The global electronics market faces a persistent threat from counterfeit components, which can compromise performance and safety. These fake parts often originate from unauthorized distributors or recycled waste streams. Implementing strict supplier vetting and authentication protocols is crucial.

Supply Chain Volatility

Geopolitical tensions, natural disasters, trade restrictions, and pandemics can disrupt component availability. For example, the U.S.-China trade war and export controls on advanced semiconductors have affected sourcing strategies worldwide.

To address this, many OEMs are reshoring or nearshoring production and exploring alternative sourcing regions such as Southeast Asia and Eastern Europe.

Long Lead Times

Certain components—especially custom ASICs, FPGAs, or specialized sensors—can have lead times exceeding 50 weeks. Accurate forecasting and early engagement with suppliers are necessary to avoid bottlenecks.

Best Practices for Effective OEM Electronic Components Sourcing

To overcome these challenges and build a robust sourcing framework, consider adopting the following best practices.

Collaborate Early with Contract Manufacturers

Partnering with a full-service electronic component sourcing provider early in the design phase allows for Design for Manufacturability (DFM) reviews and component availability checks. This proactive approach prevents costly redesigns and accelerates time-to-market.

Leverage Dual-Sourcing Strategies

Whenever possible, identify second-source suppliers for critical components. This redundancy ensures continuity if one vendor experiences shortages or quality issues.

Use Authorized Distribution Channels

Stick to authorized distributors and franchise partners whenever feasible. While independent brokers may offer lower prices or faster delivery, they carry higher risks of counterfeit or non-compliant parts.

Invest in Supply Chain Visibility Tools

Modern ERP and PLM systems provide real-time insights into inventory levels, order status, and supplier performance. Cloud-based platforms enable seamless collaboration between OEMs, CMs, and suppliers.

Monitor Market Trends Continuously

Stay informed about industry trends such as wafer fab expansions, mergers among semiconductor companies, and shifts in raw material pricing. Subscribing to market intelligence reports from firms like Gartner or IC Insights can provide valuable foresight.

How Turnkey Solutions Simplify OEM Electronic Components Sourcing

One of the most effective ways to streamline OEM electronic components sourcing is by working with a turnkey contract manufacturer. In a turnkey model, the CM takes full responsibility for procuring all necessary components, managing inventory, and handling logistics.

This approach offers several advantages:

- Reduced administrative burden: No need to manage multiple supplier relationships.

- Improved scalability: Easily adjust production volumes without renegotiating supply contracts.

- Better cost control: Aggregated buying power leads to lower component costs.

- Faster ramp-up: Accelerated prototyping and pilot runs due to immediate access to parts.

For startups and mid-sized OEMs, turnkey solutions eliminate the need for large procurement teams and sophisticated inventory systems.

The Role of Technology in Modern Sourcing

Digital transformation is revolutionizing OEM electronic components sourcing. Artificial intelligence (AI) and machine learning algorithms are being used to predict shortages, optimize inventory, and recommend alternative components.

Blockchain technology is emerging as a tool for enhancing traceability and combating counterfeits by providing immutable records of component provenance.

Additionally, digital twin simulations allow engineers to test component compatibility virtually before physical assembly, reducing errors and rework.

Building Long-Term Supplier Relationships

While transactional purchasing may suffice for short-term needs, sustainable success in electronics manufacturing depends on cultivating long-term partnerships. Trust, transparency, and mutual investment in quality drive these relationships.

Regular performance reviews, joint improvement initiatives, and shared risk management plans strengthen collaboration and align goals across the supply chain.

Final Thoughts: Making OEM Electronic Components Sourcing a Competitive Advantage

OEM electronic components sourcing is no longer just a back-office function—it's a strategic lever that impacts product quality, cost structure, and time-to-market. By adopting a proactive, data-driven, and collaborative approach, OEMs can transform sourcing from a challenge into a competitive advantage.

Whether you're developing consumer electronics, medical devices, industrial automation systems, or automotive technology, the principles of smart sourcing remain the same: plan ahead, verify quality, diversify suppliers, and leverage expert partners.

If you're looking to simplify your component procurement process and focus on core innovation, consider partnering with a trusted PCB assembly manufacturer that offers integrated sourcing and manufacturing services. With the right support, you can bring your next-generation products to market faster, more reliably, and with greater confidence.